Polo Shirt Manufacturer in Turkey

Brosan Textile is a professional polo shirt manufacturer in Istanbul, Turkey, specializing in pique polo shirts, performance polos, and custom embroidered polo shirts for brands worldwide. We provide complete OEM and ODM polo shirt production with private label services.

Professional Polo Shirt Manufacturing

As a factory-direct polo shirt manufacturer, we produce premium quality polo shirts for corporate wear, sportswear brands, fashion labels, and promotional clothing companies. Our facility in Istanbul handles every aspect of polo shirt production from fabric sourcing through finished garment packaging.

We manufacture various polo shirt styles including classic fit polos with flat knit collars, modern slim fit polos, performance athletic polos with moisture-wicking fabrics, long sleeve polo shirts, polo dresses for women, and fashion-forward polos with unique design elements. Each style can be fully customized with embroidery, printing, and branded details.

Fabric Options for Polo Shirts

Fabric selection significantly impacts the polo shirt's appearance, feel, and durability. We work with premium textile suppliers to offer various fabric options:

- Pique Cotton (180-220 GSM): Classic honeycomb texture provides breathability and structure. Ideal for corporate polo shirts and casual wear. Available in single pique and double pique constructions.

- Jersey Cotton (160-200 GSM): Smooth surface with excellent drape. Lighter weight for comfort. Popular for fashion polo shirts and softer hand feel.

- Cotton-Polyester Blends: 65/35 or 50/50 ratios offer enhanced durability, wrinkle resistance, better color retention, and lower shrinkage. Ideal for workwear and uniforms.

- Performance Fabrics: Technical materials with moisture-wicking properties, UV protection, anti-microbial treatments, and quick-dry finishes. Perfect for athletic and activewear polo shirts.

Embroidery and Customization

Polo shirts are ideal for branded embroidery, and we offer comprehensive embroidery services:

Embroidery Placements: Left chest logo embroidery is the most common placement for corporate and brand identity. We also offer right chest placement, sleeve embroidery, back yoke or full back embroidery, collar embroidery for subtle branding, and pocket embroidery if pockets are included.

Embroidery Techniques: We provide flat embroidery for clean professional looks, 3D puff embroidery for raised effects, applique with embroidery for larger designs, chain stitch for decorative elements, and multi-color embroidery up to 12 colors for complex logos.

Quality Standards: Our embroidery department ensures proper backing usage to prevent puckering, correct tension settings for different fabrics, thread quality matching color standards, and final inspection of all embroidered polos for consistency.

Collar and Placket Construction

The collar and placket are defining features of polo shirt quality:

Collar Styles: Classic flat knit collars with matching fabric or contrast tipping stripes for visual interest. Ribbed collars for better shape retention. Self-fabric collars for fashion applications. Engineered collars with structured interlining for formal corporate wear.

Placket Options: Standard 2-button plackets for casual styles. 3-button plackets for slightly longer coverage. 4-button plackets for fashion-forward designs. Hidden plackets for clean aesthetics. Button-through plackets extending to hem for alternative styling.

Button Selection: We offer standard buttons in various colors, branded buttons with engraved logos, contrasting button colors for design interest, and quality button attachment with reinforcement for durability.

Private Label Services

Transform polo shirts into your branded products with complete private label services:

- Woven labels sewn into the neck seam with your brand name and care instructions

- Printed labels as cost-effective alternatives for internal branding

- Custom hang tags in various sizes showcasing your brand identity

- Individual poly bag packaging with printed branding

- Custom boxes for retail presentation or corporate gifting

- Size stickers and composition labels meeting international standards

- Barcode labels for retail distribution

Quality Control Process

Polo shirt quality depends on attention to detail throughout production:

Fabric Inspection: All fabrics are inspected for weight consistency, color accuracy against approved samples, texture and hand feel assessment, and defect identification. Pique fabrics specifically checked for honeycomb texture uniformity.

Construction Quality: Special attention to collar construction and attachment for proper lay and shape retention. Placket alignment and button placement accuracy. Sleeve setting for comfortable armhole. Side seam straightness and hem quality. Reinforcement at stress points.

Final Inspection: Each polo shirt undergoes measurement verification, collar and placket inspection, embroidery or print quality check, button security testing, overall appearance assessment, and packaging inspection before shipment approval.

MOQ and Order Information

Minimum Order Quantity: Our standard MOQ is 150 pieces per color per model. This quantity ensures efficient production setup while maintaining quality and competitive pricing. For polo shirts in white, black, and navy, you would order 150 pieces per color (450 total pieces).

Mixed size ratios are standard. A typical 150-piece order might distribute as: XS (10), S (30), M (45), L (40), XL (20), XXL (5). We adjust ratios based on your market requirements and historical sales data.

Production Timeline

Understanding production timelines helps with planning and inventory management:

- Initial Samples: 7-10 days from tech pack submission

- Fit Corrections: 5-7 days per revision if needed

- Pre-Production Sample: 5-7 days in final fabrics and trims

- Bulk Production: 25-35 days from deposit and order confirmation

- Total Timeline: 6-8 weeks from sampling to ready-to-ship

Why Turkey for Polo Shirt Manufacturing

Turkey offers significant advantages for polo shirt production:

Textile Heritage: Turkey's long history in textile manufacturing ensures skilled workforce, sophisticated fabric production capabilities, and quality control standards. Turkish pique fabrics are recognized globally for quality.

Strategic Location: Positioned between Europe and Asia provides logistical advantages. Fast shipping to European markets. Convenient time zone for business communication with Western markets. Established export infrastructure.

Competitive Advantage: Quality comparable to European production with more competitive pricing. Shorter lead times than Asian alternatives. Flexibility and service-oriented approach. English proficiency in business environment facilitates smooth communication.

Polo Shirt Size Guide & Measurements

Our polo shirts feature classic and modern fits. All measurements in centimeters (flat lay). Perfect for corporate, casual, and sporting applications.

| Size | Chest (cm) | Length (cm) | Shoulder (cm) | Sleeve (cm) |

|---|---|---|---|---|

| XS | 86-91 | 68 | 41 | 18 |

| S | 91-97 | 70 | 43 | 19 |

| M | 97-102 | 72 | 45 | 20 |

| L | 102-107 | 74 | 47 | 21 |

| XL | 107-112 | 76 | 49 | 22 |

| 2XL | 112-117 | 78 | 51 | 23 |

| 3XL | 117-122 | 80 | 53 | 24 |

Note: Polo shirts typically have a relaxed fit through the chest and torso. Slim-fit polos reduce chest width by 2-3cm. Classic fit polos are boxier. Sleeve length is measured from shoulder seam to cuff edge.

Polo Shirt Fabric Comparison Guide

Choose the perfect fabric for your polo shirt based on your brand positioning, target market, and quality requirements.

| Fabric Type | GSM Range | Feel & Texture | Durability | Shrinkage | Best For |

|---|---|---|---|---|---|

| Cotton Pique (Single) | 180-220 GSM | Textured, breathable, classic | Very Good | 3-4% | Corporate polo, classic styling, everyday wear |

| Cotton Pique (Double) | 220-260 GSM | Heavier, structured, premium | Excellent | 3-4% | Premium polo shirts, luxury brands, retail |

| Performance Polyester Pique | 160-200 GSM | Moisture-wicking, quick-dry, athletic | Excellent | <1% | Sports polo, golf shirts, athletic teams |

| Cotton-Poly Blend (65/35) | 180-220 GSM | Soft, wrinkle-resistant, easy-care | Excellent | 2-3% | Uniform programs, corporate wear, hospitality |

| Jersey Knit Polo | 160-200 GSM | Smooth, soft, drapey, casual | Good | 3-4% | Fashion polo, retail, casual brands |

| Honeycomb Pique | 200-240 GSM | Unique texture, breathable, distinctive | Very Good | 2-3% | Premium retail, designer brands, fashion-forward |

Need help choosing? Our fabric specialists can recommend the ideal material based on your target price point, market segment, and design requirements. Contact us for personalized fabric selection guidance.

Popular Polo Shirt Style Variations

Explore the most requested polo shirt styles from our B2B clients. Each variation can be fully customized to match your brand aesthetic and target market.

Classic 2-Button Polo

Traditional polo with ribbed collar, 2-button placket, and short sleeves. Timeless design for all occasions.

3-Button Polo

Extended placket with 3 buttons for more formal appearance. Popular in corporate settings.

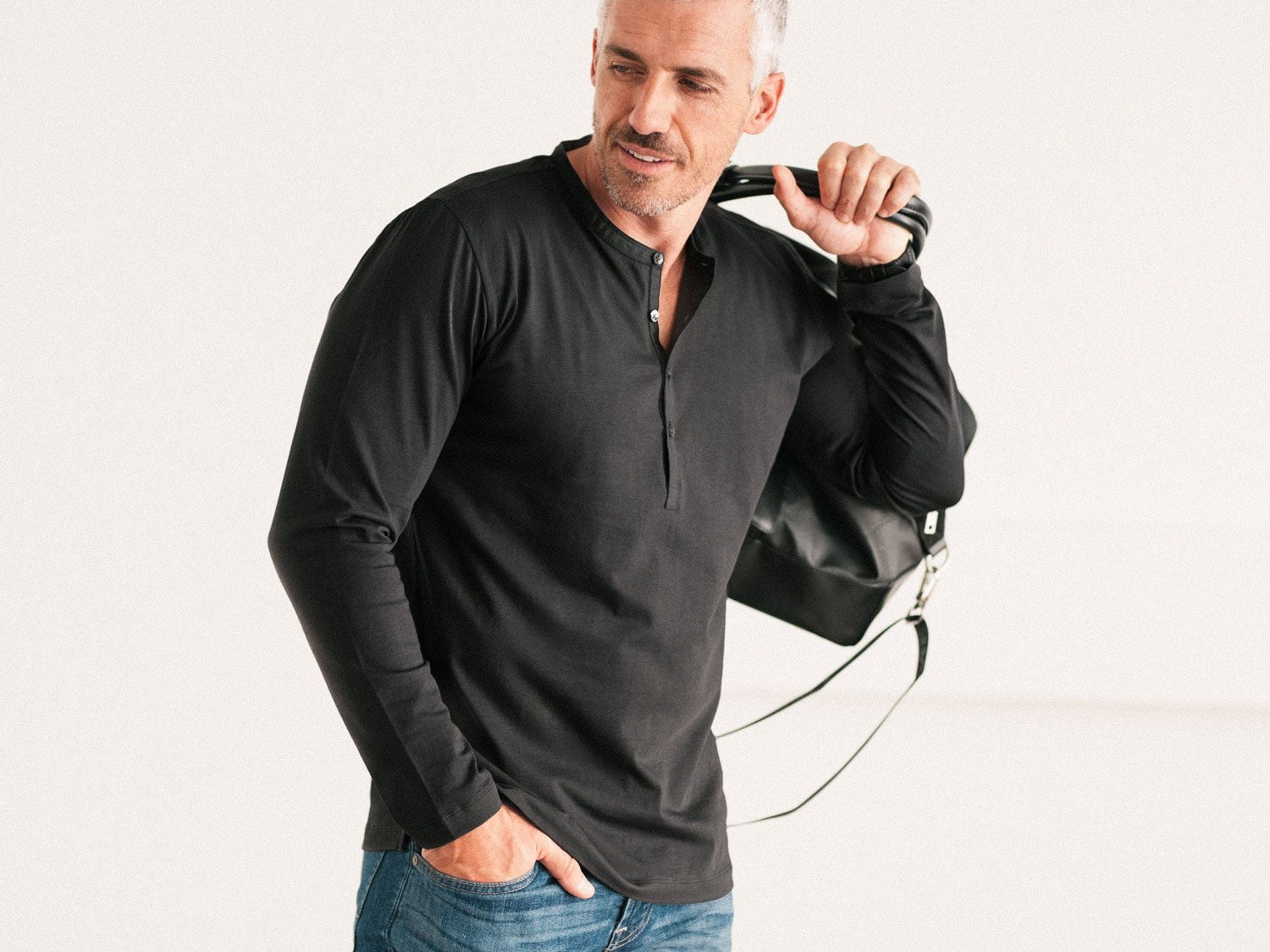

Long Sleeve Polo

Classic polo styling with long sleeves. Ideal for transitional seasons and layering.

Performance/Golf Polo

Athletic polo with moisture-wicking fabric, side vents, and UV protection. Built for active wear.

Fashion Polo with Contrast Details

Modern polo featuring contrast collar, placket, or stripes for visual interest.

Henley-Style Polo

Collarless polo with button placket, combining polo functionality with casual henley aesthetic.

Custom Styles: Don't see your desired style? We can develop any polo shirt design based on your sketches, reference images, or tech packs.

Polo Shirt Customization Options

Transform your polo shirt into a unique branded product with our comprehensive customization services. All options available with competitive MOQs.

Embroidery

- • Left Chest Logo

- • Sleeve Logo

- • Back Neck

- • Full Back Embroidery

- • Multi-Position

Printing

- • Screen Print

- • Heat Transfer

- • Sublimation (All-Over)

- • Distressed Print

- • Placement Print

Collar Options

- • Ribbed Collar

- • Flat Knit Collar

- • Contrast Collar

- • Striped Collar

- • Self-Fabric Collar

Placket & Buttons

- • 2-Button

- • 3-Button

- • 4-Button

- • Contrast Buttons

- • Custom Button Colors

- • Hidden Placket

Labels & Tags

- • Woven Labels

- • Heat Transfer Labels

- • Neck Tape

- • Side Seam Labels

- • Hang Tags

Special Features

- • Side Vents

- • Contrast Tipping

- • Chest Pocket

- • UV Protection

- • Moisture-Wicking Treatment

Need a Custom Quote?

Combine multiple customization options for your polo shirt order. Our team will provide detailed pricing and timeline estimates.

Get Custom Quote →Polo Shirt Order Process Timeline

Our streamlined 7-step process ensures quality, transparency, and on-time delivery for your polo shirt manufacturing orders.

1. Design Specification

1-2 daysReview polo style, collar type, placket design, and fabric preferences.

2. Sample Development

7-10 daysCreate pre-production samples with exact fabric, fit, and details.

3. Fit & Detail Approval

2-4 daysYou review collar structure, button quality, fit, and embroidery placement.

4. Material Procurement

5-8 daysSource pique fabric, ribbing, buttons, and labels for production.

5. Bulk Manufacturing

15-20 daysCutting, collar/placket construction, sewing, embroidery, QC.

6. Final QC & Packaging

2-3 daysQuality inspection, individual poly-bagging, labeling.

7. Shipping Preparation

1-2 daysExport documentation and logistics arrangement.

Total Timeline: 33-43 Days

From initial consultation to shipping, expect approximately 4-6 weeks for complete order fulfillment. Rush orders available with adjusted timelines.

Frequently Asked Questions

What is the MOQ for polo shirt manufacturing?

Our minimum order quantity is 150 pieces per color per model. This ensures efficient production while maintaining quality standards and competitive pricing. For brands ordering multiple styles, we can offer flexible arrangements.

What fabric types do you use for polo shirts?

We primarily work with pique cotton (180-220 GSM), jersey cotton (160-200 GSM), cotton-polyester blends for durability, and performance fabrics with moisture-wicking properties. Each fabric type offers different benefits for various market segments.

Can you embroider logos on polo shirts?

Yes, we specialize in polo shirt embroidery. We can place logos on the chest, sleeves, back, or collar. Our embroidery capabilities include single-color, multi-color, 3D puff embroidery, and applique with embroidery combinations.

What collar and button options are available?

We offer various collar styles including classic flat knit collars, ribbed collars, tipping stripes, and engineered collars. Button options include 2-button and 3-button plackets, branded buttons with engraving, and custom button colors matching your brand.

Do you offer women's polo shirts?

Yes, we manufacture both men's and women's polo shirts with appropriate fit adjustments, side seaming for women's styles, and sizing specific to each gender. We can develop patterns based on your fit preferences.

What printing methods do you use on polo shirts?

We provide screen printing for larger designs, DTG (direct-to-garment) for detailed prints, heat transfer for special applications, and discharge printing on dark colors. Print placements include chest, back, sleeves, and collar.

Can you add pockets to polo shirts?

Yes, we can add chest pockets in various styles including patch pockets with and without flaps, embroidered pocket edges, and interior pockets. Pocket details can be customized to match your design specifications.

What is the production timeline for polo shirt orders?

Sampling takes 7-10 days. Bulk production requires 25-35 days depending on quantity and customization level. Total timeline from sampling to shipment is approximately 6-8 weeks for new designs.

Do you offer private label services for polo shirts?

Absolutely. We provide woven neck labels, printed labels, hang tags, custom packaging, barcode labels, and size/care labels. Complete private label packages are available to establish your brand identity.

What quality control measures do you implement?

We inspect fabric quality upon arrival, verify pattern accuracy during cutting, monitor stitching quality especially on collars and plackets, check button attachment strength, inspect embroidery quality, and conduct comprehensive final inspection before packaging.

Recommended Fabrics

Piqué

180-220 GSM

Classic textured fabric for traditional polo shirts. Excellent breathability and shape retention.

View Details →Jersey

180-200 GSM

Smooth alternative to piqué. Great for modern, fitted polo designs.

View Details →Cotton-Poly Blend

160-200 GSM

Durable mix with reduced wrinkling. Perfect for corporate and sports polos.

View Details →Custom Polo Shirt Manufacturing & Private Label Production

Private Label Services

As a leading custom polo shirt manufacturer in Turkey, we produce branded polo shirts with your designs, labels, and packaging. Our custom polo factory in Turkey specializes in private label polo shirt production including piqué polo shirts, performance polos, and fashion polo styles.

- • Full branding: Custom labels, tags, packaging

- • Complete private label polo collections for brands

- • MOQ 150 pieces per color - ideal for growing brands

Custom Production

Our private label polo shirt manufacturer services include embroidery, screen printing, applique, and custom buttons. As a modern polo shirt factory in Turkey, we work with piqué, jersey, and performance fabrics to create custom polo shirt collections for global brands.

- • Custom designs: Your patterns, colors, collars

- • Full customization: Fabric, embroidery, buttons

- • Technical samples within 7-10 days

What Our Clients Say

"Brosan delivered 600 custom embroidered polo shirts for our corporate event. The pique fabric quality was excellent, and the embroidery work was flawless. Production timeline was exactly as promised."

Michael Anderson

Corporate Solutions Ltd., UK

"We've been sourcing performance polo shirts from Brosan for our sports brand for 2 years. Their moisture-wicking fabrics and consistent quality keep our customers happy. Great partner for private label production."

Sarah Martinez

ActiveWear Pro, USA

"The team at Brosan helped us develop custom polo designs with branded buttons and unique collar details. Their sampling process was thorough, and the final products exceeded expectations. Highly professional."

Thomas Weber

Premium Fashion GmbH, Germany

Industry Insights & Guides

Technical Specifications

| Specification | Details |

|---|---|

| Fabric Weight (GSM) | 180-240 GSM (Lightweight: 180-200, Standard: 200-220, Premium: 220-240) |

| Collar Types | Classic 2-Button, 3-Button, Button-Down, Ribbed Collar, Flat Knit, Contrast Tipping |

| Placket Options | 2-Button, 3-Button, 4-Button, Hidden Button, Contrast Button |

| Fit Styles | Slim Fit, Classic Fit, Athletic Fit, Relaxed Fit, Women's Fitted |

| Size Range | XS, S, M, L, XL, 2XL, 3XL, 4XL, 5XL (Custom sizing available) |

| Color Options | 50+ stock colors, Custom PMS/Pantone colors (MOQ 200 pcs per custom color) |

| Features | Ribbed Collar/Cuffs, Side Vents, Reinforced Placket, Contrast Tipping, Moisture-Wicking |

Production Capacity & Lead Times

Dedicated production lines with specialized equipment

From bulk order confirmation to shipment ready

Consistent performance with reliable quality

Production Expertise

Our polo shirt production facility operates 7 specialized lines with rib attachment and placket machines. We produce classic pique polos, performance moisture-wicking styles, and fashion polos with custom collars and tipping.

Care & Maintenance Guide

Washing Instructions

Machine Wash Cold (30°C / 86°F)

Cold water prevents shrinkage and color fading

Turn Inside Out

Protects collar, placket, and any embroidered logos

Use Mild Detergent

Avoid bleach which can damage pique fabric texture

Gentle Cycle

Maintains collar shape and prevents stretching

Drying & Storage

Tumble Dry Low or Air Dry

High heat can shrink collars and damage ribbing

Remove Promptly

Prevents wrinkles, especially on placket area

Iron on Medium Heat

Iron collar flat to maintain crisp appearance

Hang or Fold

Hang on proper hangers to prevent collar distortion

Pro Tip: For polo shirts with contrast tipping or embroidered logos, wash in cold water to prevent color bleeding. Always button up placket before washing to maintain shape.

Industry Applications & Use Cases

Corporate & Uniform

Custom branded polo shirts for corporate uniforms, hospitality, retail staff, and professional service industries.

- • Corporate uniforms

- • Hotel & hospitality

- • Retail staff

- • Professional services

Golf & Country Clubs

Performance polo shirts for golf courses, country clubs, tennis clubs, and resort pro shops requiring quality and style.

- • Golf pro shops

- • Country clubs

- • Tennis clubs

- • Resort wear

Promotional Products

Branded polo shirts for corporate gifts, trade shows, employee recognition, and promotional campaigns.

- • Corporate gifts

- • Trade show giveaways

- • Employee recognition

- • Brand merchandise

Fashion Retail

Contemporary polo designs for fashion brands, department stores, and lifestyle retailers seeking quality basics.

- • Fashion brands

- • Department stores

- • Boutique retailers

- • Lifestyle brands

Sports Teams

Team polo shirts for sports clubs, coaching staff, athletic organizations, and tournament merchandise.

- • Sports clubs

- • Coaching staff

- • Athletic organizations

- • Tournament merch

Schools & Universities

Uniform polo shirts for educational institutions, private schools, and university bookstores.

- • School uniforms

- • University bookstores

- • Campus stores

- • Educational programs

Related Products

Explore more manufacturing options from our product range